A Software Company as a Manufacturer

Isembard is positioning itself as a new kind of manufacturing company, one built around software rather than machinery, and one that grows not through mega-factories but through a network of trained franchise operators. The London-based startup, founded by Alexander Fitzgerald, believes the West’s industrial decline can be reversed by giving individuals and small businesses the tools, training, and AI infrastructure to run high-performance factories of their own. While Isembard started across the pond, its revolutionary franchise model and AI-driven ecosystem are on course to generate a ripple effect across the United States, from its first US-based hub in Texas.

At the heart of Isembard is MasonOS, an AI-powered operating system that acts as the brain of each factory in its network. The system manages everything from quoting and scheduling to predicting defects and adjusting production in real time. Live sensor data feeds continuously into MasonOS, giving it the ability to detect small deviations on the factory floor and correct them before they balloon into costly errors.

This software-first approach allows Isembard to streamline production and deliver consistent quality, but it also enables something more unusual: a scalable factory model that others can operate.

Isembard

- Founder and CEO: Alexander Fitzgerald

- “Software-first” manufacturing company

- MasonOS

- AI-driven Operating System for manufacturing franchise businesses

- Headquartered in London, England, UK

- Factory in Exeter, England, UK

- Factory in Gosport, England, UK

- North American Hub in Dallas-Fort Worth (Carrolton), US

What a Factory Franchise Looks Like

Where traditional manufacturers expand by building new facilities, Isembard grows by developing franchisees, individuals who apply, train, and eventually run their own Isembard-powered factories. It’s a model more familiar in food service or retail than in advanced manufacturing, but the company believes the combination of AI, standardized processes, and deep training makes it possible.

Path Towards Become a Franchisee

Step 1 (Selection and Agreement)

Successful completion of Isembard’s selection process and signing the franchise agreement

- Applicant sends CV

- Initial Call

- A brief interview about applicant’s goals and answer questions

- Thorough Application Form

- Detailing applicant’s leadership and manufacturing experience, as well as financial status

- Onboarding & Support Guide

- Receive informational guide on how Isembard supports factory set-up

- Receive information regarding training on factory operations and MasonOS

- Assessment Day

- Franchise Applicant visits an Isembard factory to get firsthand experience and immersion into operations and team culture

- Franchise Offer

- Successful applicants receive a formal offer to set up an Isembard franchise

Step 2 (Training)

Isembard provides comprehensive training and work with the Franchisee to establish their own factory using Isembard’s expertise

Step 3 (Factory Launch)

Franchisee launches their very own factory

- Obtains incoming streams of work projects (business) directed to their factory,

- Gets the cutting-edge technology to accomplish the work

Step 4 (Scaling Up)

Franchisee grows the business by expanding with additional machines, staff, and locations

Isembard’s Manifesto:

- Economic Prosperity

- “Manufacturing drives growth. Every new factory, every product made, strengthens the economy and creates lasting opportunity.”

- National Security

- “Sovereign capability matters. Control over what we build and how we build it ensures resilience and independence.”

- A Sense of Purpose

- “We are restoring pride in making things that matter – giving people, communities and nations something to stand behind again.”

Brief clip about Isembard:

AI-Driven Success

MasonOS

- Proprietary AI-driven software

- 10x faster quoting and production cycles

- AS9100D compliant workflows

- Predict and prevent defects through machine learning

- Closed-loop feedback: Control system feature where sensors continuously monitor the machine’s actual position and speed and feed that data back to the computer controller (If any deviation from the programmed path is detected, the system makes instant, automatic corrections)

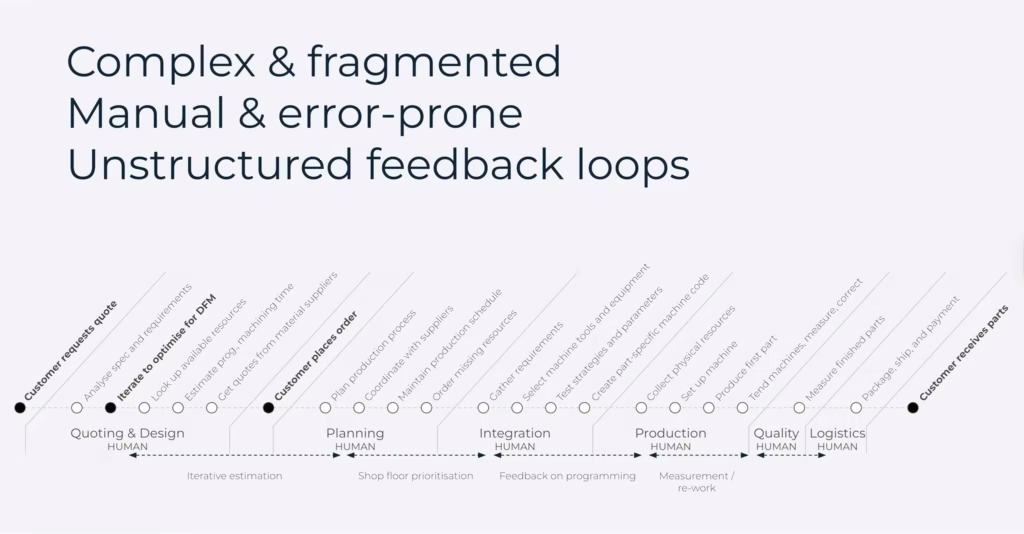

Isembard’s streamlined process significantly reduces the time and effort required by human workers, from the moment a client submits a request, to the time the client receives the finished product. This is possible, thanks to the AI magic performed by MasonOS.

Traditional, fragmented feedback process:

Isembard’s process:

- Design Upload – A customer submits a 3D model

- Instant Quote – MasonOS analyses geometry, material and process for cost + lead time

- Prototype Run – Automated scheduling and machine assignment

- Production Scale – Real-time adjustments optimise output across factories

- Delivery – Parts shipped faster than traditional suppliers

Andrew Kramer, the University of Oxford educated Head of Strategic Deployments at Isembard, explained how their process is simplified, and saves tremendous resources in time, and cost, while leading to a increased productivity. Additionally, with input from Isembard’s technical design expertise, it could quite possibly result in a better finished product:

“Well, I would say that we want to be doing all of these things with all of our customers, and yet, of course, we can do it through the system, and the fact that we have MasonOS to help industrialize and automate a lot of the factory and the processes, but other factories would consume a lot of people’s time.“

“We can clean up that point and really provide that proper work with our customers. To give you an example, with one of our customers, we’re not just manufacturing parts, we’re also helping them on the design. Just to give you a sense of what that means, it means working with their design engineers and helping them find ways where they can tweak the design, make changes, but it still retains the same performance, or, in fact, increases the performance, but it becomes cheaper, quicker, and easier for the manufacturer because that’s better for them, and it’s better for us. It isn’t easy for the manufacturer. We will, of course, pass that benefit on to them and help them grow more. We can do the design for the manufacturer“ – Andrew Kramer, Head of Strategic Deployments at Isembard

AI Acceptance and Integration

With AI becoming more important than ever in the manufacturing sector, the Manufacturing Leadership Council’s (MLC) Future of Manufacturing Project explored how manufacturers can prepare for the digital future of industry. Their focus this year, titled “AI-Centric Factories of the Future”, examines the growing role of artificial intelligence in transforming manufacturing. From production lines to executive decision-making, and across suppliers, employees, and customers, AI is set to drive greater efficiency, innovation, and strategic advantage. The MLC published the findings of a survey report of attendees from a MLC conference from December 2024.

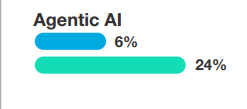

Only 6 percent of the

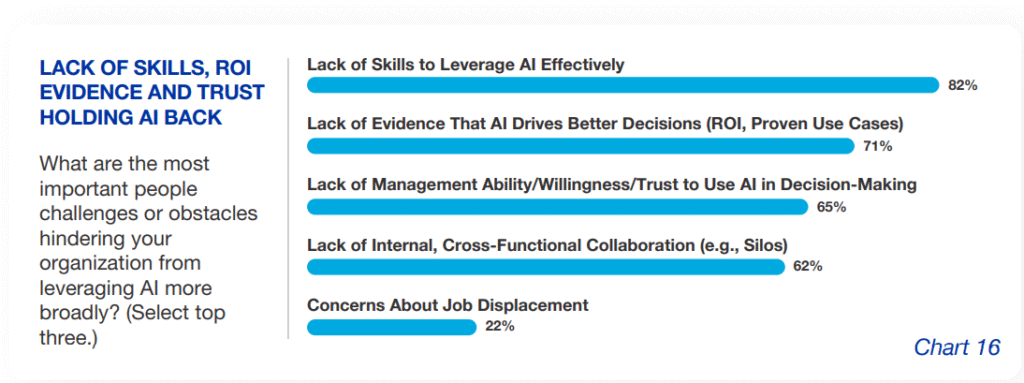

AI Skills

Not surprisingly, 82% surveyed felt they lacked the skills to leverage AI effectively. As part of the second step of Isembard’s path towards becoming a franchisee, those who pass their initial selection process will acquire the training and skills to successfully utilize MasonOS. Leveraging this powerful, proprietary AI-driven software will keep franchisee ready to face the future challenges of AI-integrated manufacturing head on!

Job Displacement or Job Protection?

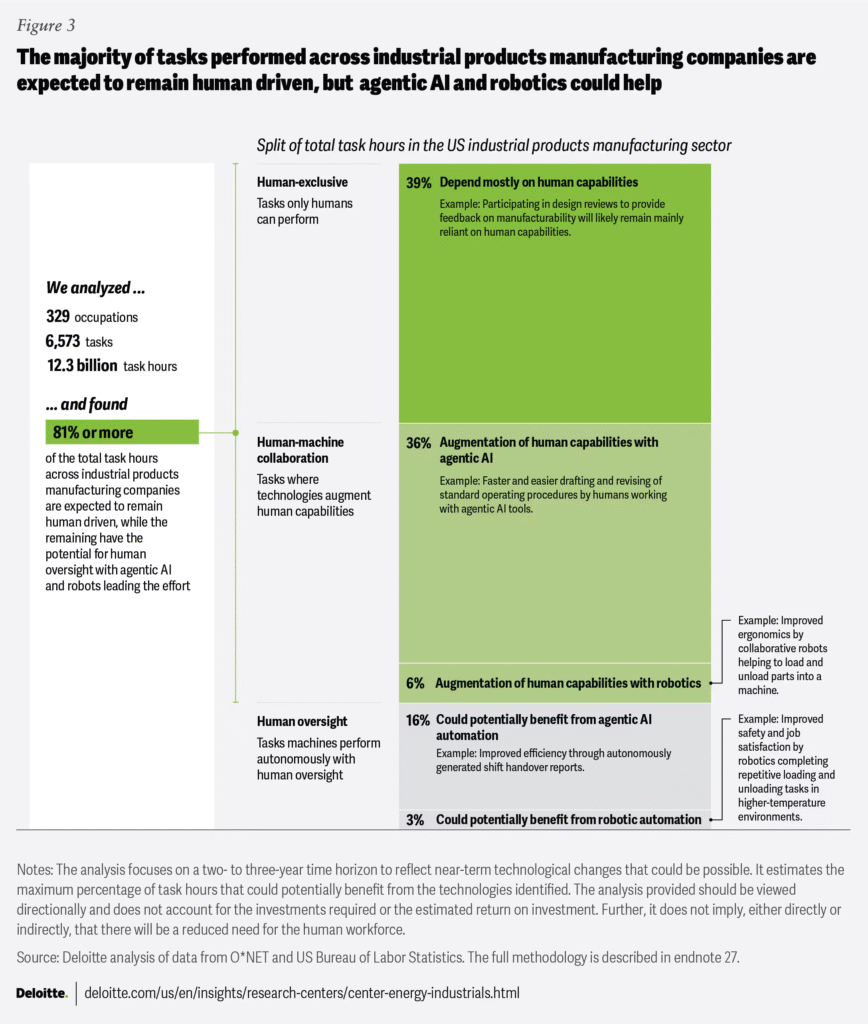

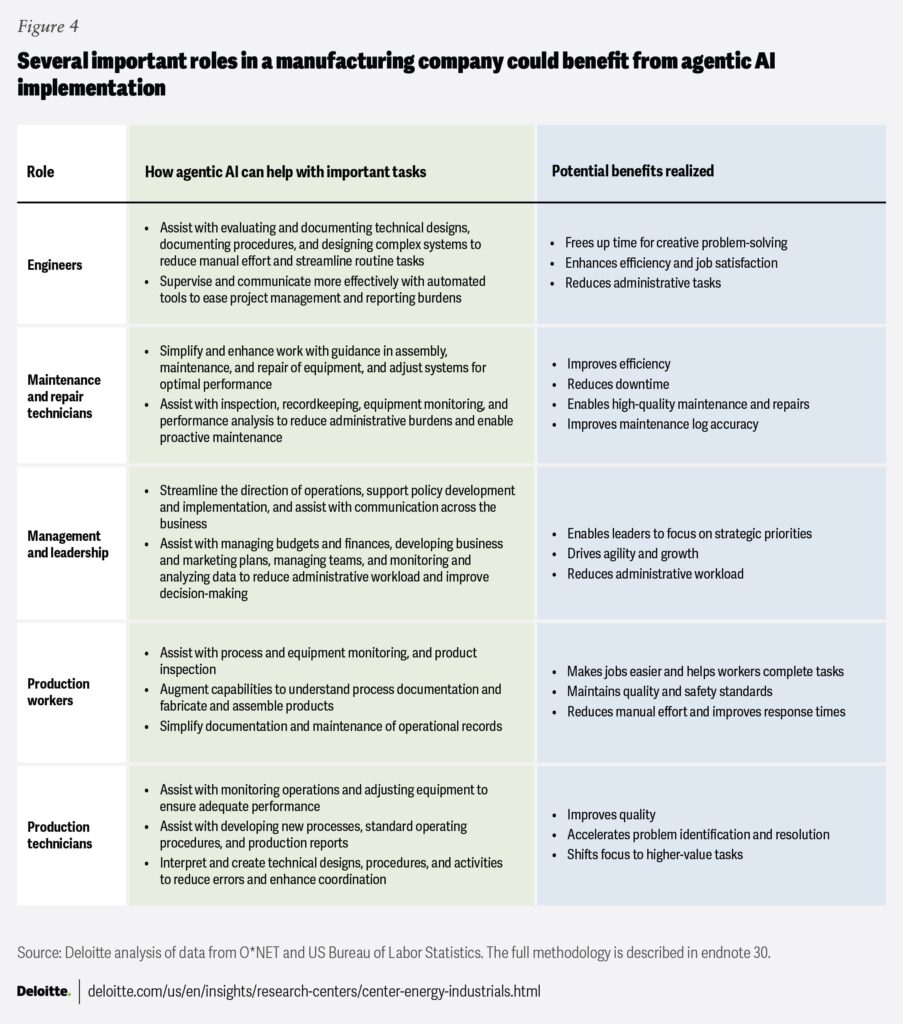

The MLC also reported that 22% of those surveyed had concerns about job displacement as a consequence of AI adoption. However, according to a report by Deloitte, 81% of task hours are projected to remain human-driven among the companies manufacturing industrial products.

By staying relevant within modern manufacturing, and having the ability to harness AI for maximizing efficiency, accuracy, and speed across all parts of business of manufacturing, jobs in America (and the West as a whole) can become more competitive and have a dramatically increased chance of remaining onshore. Not only can Isembard’s MasonOS help achieve this, but it may actually help create many manufacturing jobs that have been offshored in the past. This will be explained shortly.

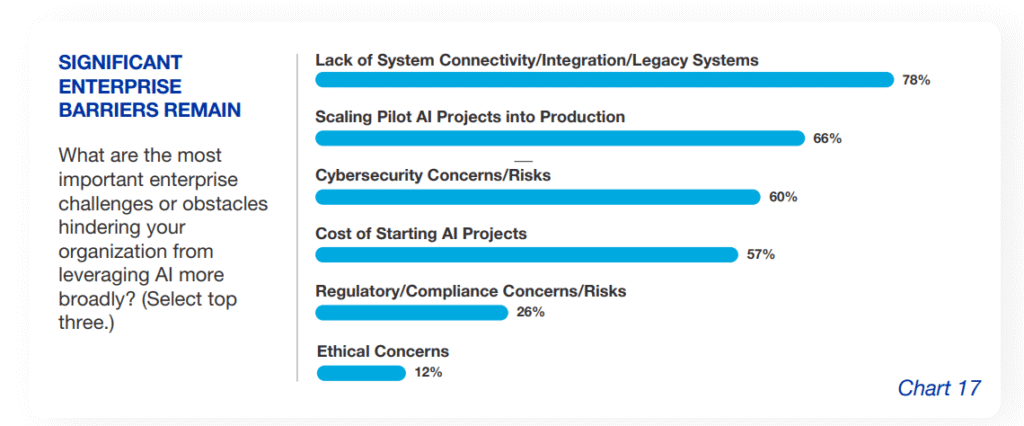

AI Integration

The “Lack of system connectivity/Integration/Legacy Systems” was noted as the “most important enterprise challenge” for 78% of those surveyed, preventing their organization/business from leveraging AI more adequately. The experts at Isembard have already figured out all the complexities and intricacies of AI for their franchisees, and thereby by proxy, for the clients of these franchisees. With AI fully integrated into MasonOS and Isembard’s franchise ecosystem from the get-go, Isembard’s franchisees can focus on doing what they do best: fulfilling orders, making business connections, and manufacturing for their communities.

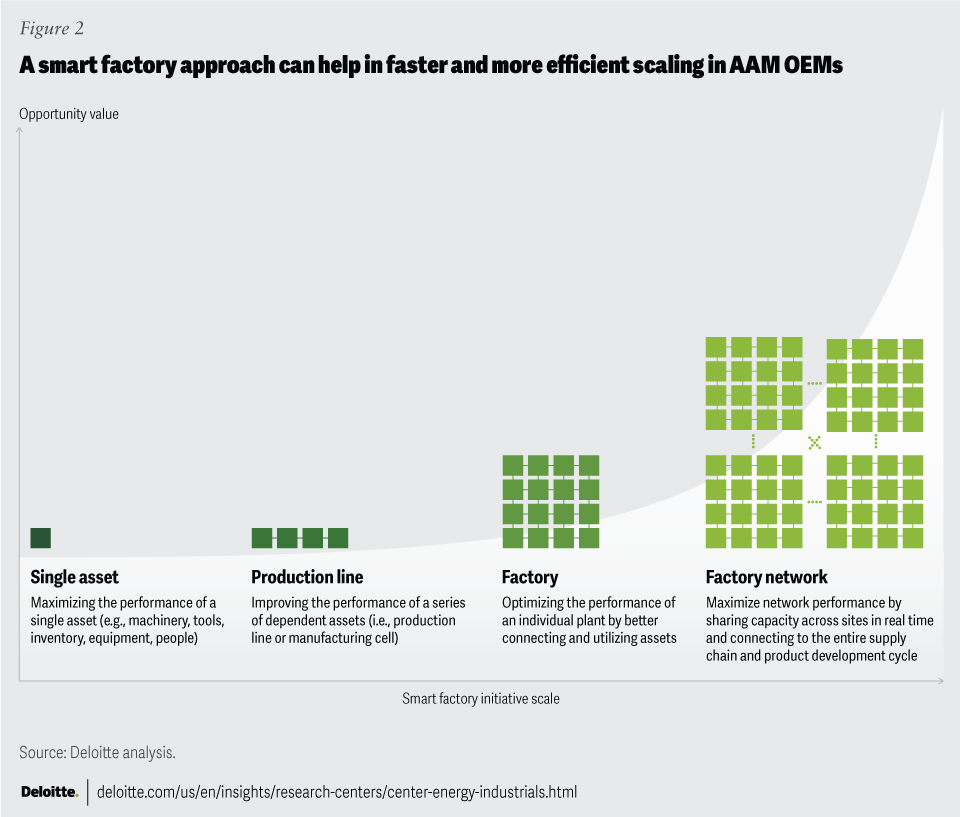

Scaling AI Projects

Of those surveyed, 66% expressed concerns of “Scaling Pilot AI Projects Into Production”. With Step 3 (obtaining the hardware and technology) and Step 4 (scaling) of Isembard’s franchise processes, factories will be able to scale their AI pilot projects into production in the most efficient way possible.

Manufacturers should focus on opportunities with the potential to deliver maximum value to their core business and return on investment (ROI) at scale. This means that prioritization should also consider all resources necessary to implement the agentic AI solution and those that will be needed to support and maintain it at scale, including costs, talent, data, and technology. A thorough and data-backed approach that considers these important factors could be essential to avoid investments in pilots that may not scale effectively, or perhaps not deliver the expected value. This “understand scale first” domain-focused approach can also help to concentrate resources on the highest-value opportunities.

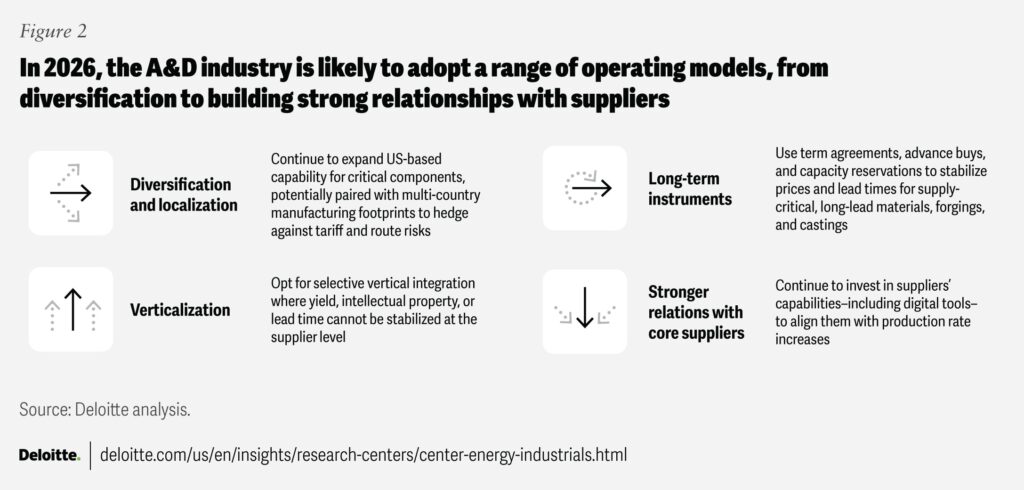

2026 Manufacturing Industry Outlook – From vision to value: A road map for enterprise transformation in manufacturing with agentic AI (published by Deloitte)

As Isembard’s Head of Strategic Deployments, Andrew Kramer, explains:

“We can help, for example, with the procurement and supply chain. Again, we do that in an extremely innovative and effective way, and actually using support through the assembly platform where we’re deploying engineers into our customers’ production facilities to help them scale up production. This is all obviously powered by that software backbone.

It’s responsive, whether our customers are small, medium, large. Just because a company is a large enterprise doesn’t mean that they’re not themselves automating rapid prototyping and rapid innovation. They’re actually doing some of our most responsive, fast-leaping work with rapid deployment and processing, i.e., self-manufacturing designs, which are increasingly manufactured, so that they can process between the final design and do that as quickly as needed, which is one of the largest real-time development models.” – Andrew Kramer, Head of Strategic Deployments at Isembard

Cybersecurity

Additionally, 60% of those interviewed in the survey declared “cybersecurity risks” was one of the most significant obstacles to leveraging AI more broadly in their organization. Isembard has built-in cybersecurity, which allows their franchise to manufacture for security sensitive industries such as military/defense and nuclear energy.

“These trends are expected to continue into 2025, with the potential for broad-based operationalization of many technologies, from artificial intelligence and advanced air mobility (AAM) to unmanned systems. Over the past year, AI has seemingly become ubiquitous, potentially indicating that companies in the sector are growing more and more comfortable with the technology. In 2025, AI is likely to help accelerate progress in various areas, including enhancing aftermarket services and optimizing supply chain.”

Source: Deloitte’s 2025 Aerospace and Defense Industry Outlook

Agentic AI in Manufacturing

“By 2026, agentic AI is expected to progress from pilot projects to scaled deployments, with the most visible advances occurring in the decision-making, procurement, planning, logistics, maintenance, and administrative functions.”

– Advanced air mobility: Achieving scale for value realization. Deloitte Research Center for Energy & Industrials. Deloitte Insights. Link here

“While pilot programs in AI-powered defect detection and automated inspection are underway, scaling these solutions remains difficult. The push to increase production rates, especially for munitions and aerospace components, may accelerate experimentation, but full-scale industrialization is unlikely in the near term.”

Source: 2026 Aerospace and Defense Industry Outlook by Deloitte

With more adoption and widespread use of MasonOS via clients outsourcing manufacturing to Isembard franchises, full-scale industrialization using agentic AI will be become more prevalent, and lead to the normalization of its use. The fact that implementation of this critical technology is still not utilized or underutilized by some manufacturers, merely points to the potential and opportunity for Isembard’s growth. With data collected on the reduced manpower requirements , time, and material waste (from less defects and parts being scrapped), Isembard’s franchise factories operating with MasonOS, will create savings that manufacturing businesses cannot ignore. This will in-turn, leader to further business with Isembard franchises, as well as an ever-increasing pool of clients. The result will be a positive feedback loop, and a snowball effect for Isembard franchises.

Industrial Decline in the West, and Reversing it

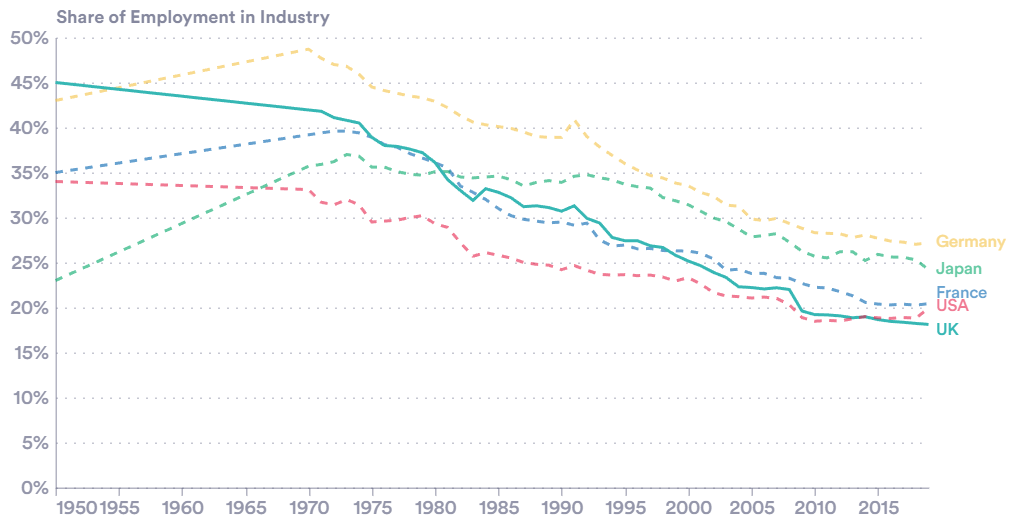

The percentage of employment in the industrial sector has been on a steady decline in the West. While Germany has performed far better than its peers such as France and the UK, (or USA for that matter), there needs to be drastic changes across the board to reverse the trend.

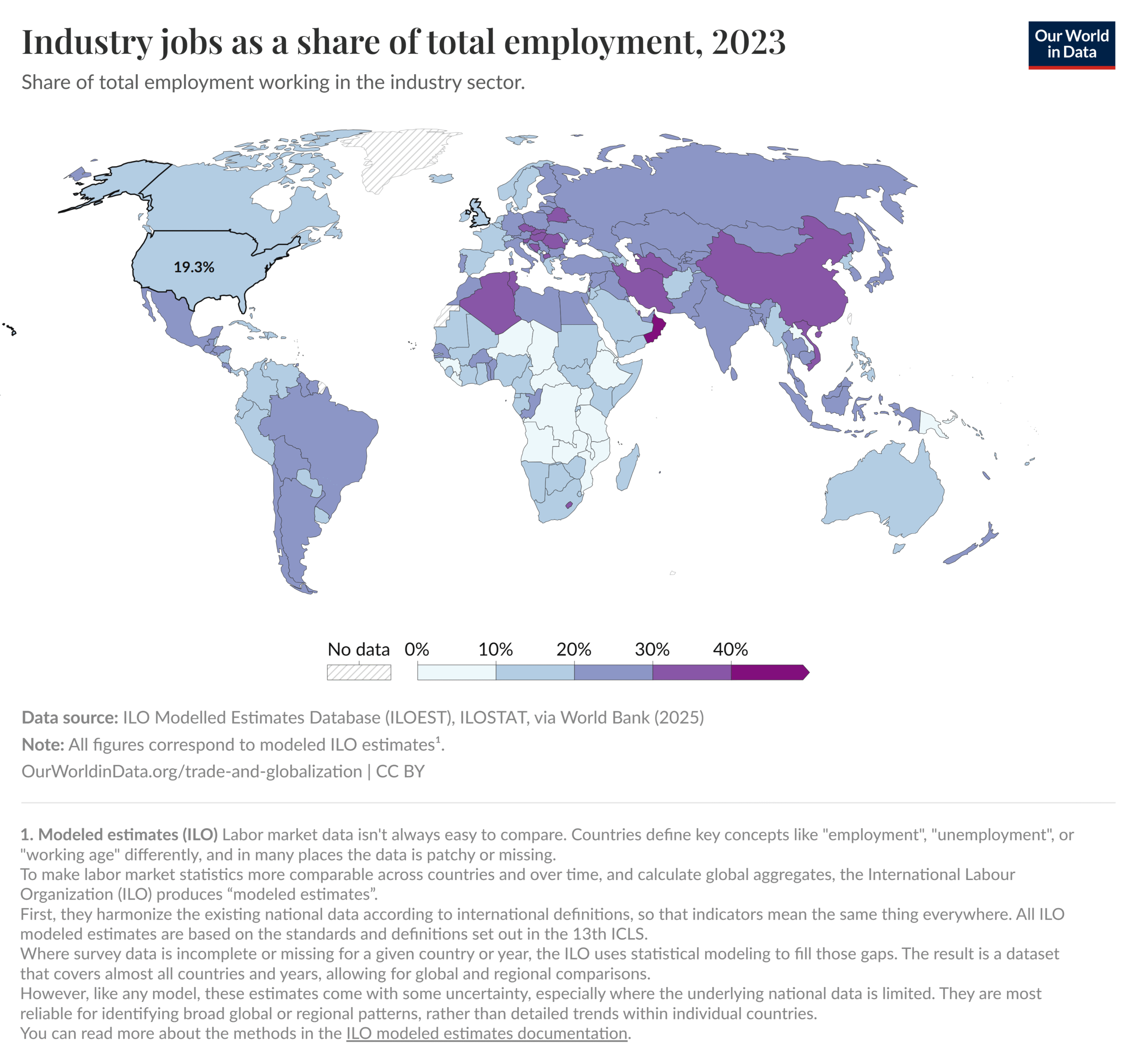

However, all these industry jobs aren’t disappearing. They must go somewhere as many essential items for a modern life need to be manufactured, and even what could be considered “non-essential” goods may create enough of a consumer demand that warrant their production by companies seeking to make money from the production and sales of such goods. China, India, Vietnam, Cambodia, Indonesia have filled this gap in manufacturing, while the leaders in the West (in the past few decades) turned their backs on the future of manufacturing (as well as the West’s legacy). A point Isembard’s founder and CEO Alexander Fitzgerald has championed, is that this trend doesn’t need to be permanent. Rather, it can be reversed through implementing Industry 4.0 frameworks, which will be discussed in the following paragraph.

Fourth Industrial Revolution (Industry 4.0)

Industry 4.0, often called the Fourth Industrial Revolution, marks a major shift in the way modern industries operate. It brings together intelligent machines, interconnected devices, and real-time data to create smarter and more responsive production environments. Instead of relying on isolated systems, factories and services now use networks that allow equipment, software, and people to communicate seamlessly. This evolution is driving more efficient processes, greater flexibility in meeting customer needs, and entirely new opportunities for innovation across the global economy.

Isembard, envisioned as a forward-thinking architect of digital systems, and MasonOS, a streamlined operating platform built for adaptability, synergistically embody the spirit of the Fourth Industrial Revolution. In an era defined by cyber-physical integration, AI-driven automation, and ubiquitous connectivity, their partnership represents how intelligent design and flexible software can power Industry 4.0. By bridging human creativity with machine efficiency, Isembard and MasonOS illustrate the shift toward systems that learn, collaborate, and evolve, thereby reshaping how industries operate and how innovation unfolds. In such a system created by Isembard, rather than replacing the human workers, the AI ecosystem is an extension of their own creativity and brilliance.

By either operating one’s very own Isembard franchise, or having a business subcontracting manufacturing projects to an Isembard factory, businesses can stay ahead of the game and be in-line with the big players. Industry leaders like International Motors, which makes diesel and electric trucks, utilizes Industry 4.0 principles to stay competitive and “support a leaner manufacturing output”. Isembard provides franchisees the ability to work at a top level within an Industry 4.0 framework, which keeps them competitive and aligned with the standards their clients require in an increasingly tech-dependant world.

“Industry 4.0 principles have been incorporated to connect digital and physical technologies, allowing the plant to be more connected and easily make data-driven decisions. Operating with a data-driven approach helps to focus on sustainability goals and metrics in addition to supporting a leaner manufacturing output.

In the future, Navistar plans to begin operations at the Advanced Technology Center (ATC) on-site, which accelerates implementation of emerging technologies and Industry 4.0 technologies within the commercial trucking space. The ATC is focused on product development, testing and validation efforts supporting the company’s strategy, and will be a key location for future research and development footprint with a focus on zero-emission components, software and autonomous technologies.”

Source: March 23, 2022 Press release from Navistar (currently International Motors)

“We are incorporating the latest manufacturing principles – digital factory, connected machinery, robust lean manufacturing processes and cloud analytics – to enable predictive quality and maintenance, and allowing data-driven decisions to be made on the shop floor in real time.” – Mark Hernandez, Executive Vice President, Global Manufacturing and Supply Chain, International Motors (March 23, 2022)

eVTOL Manufacturing

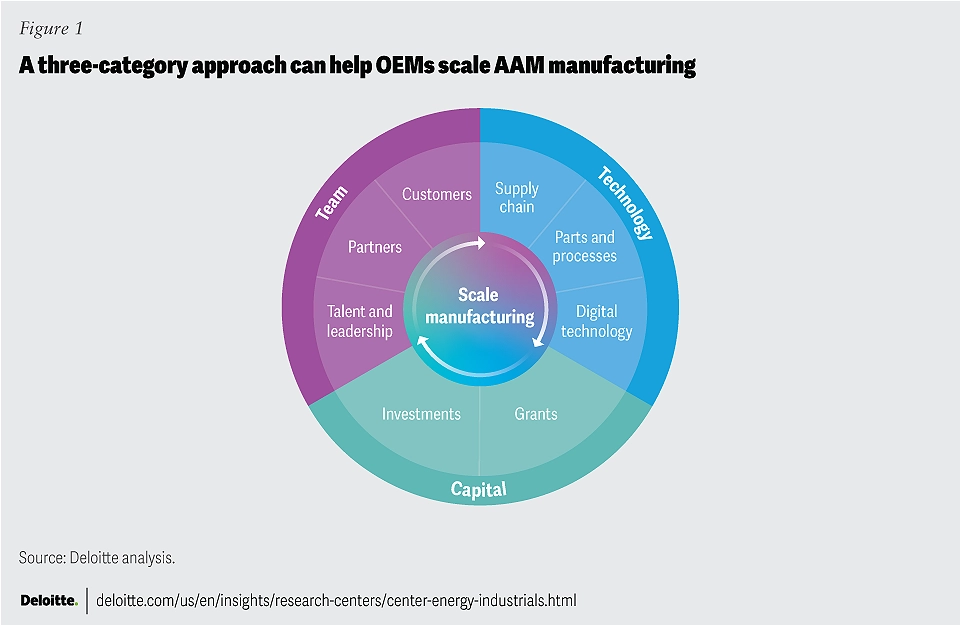

The 2023 Deloitte Research Center for Energy & Industrials analysis of the advanced air mobility (AAM) market underscores the enormous economic opportunity, and equally significant challenges for eVTOL manufacturers. With more than 13,000 orders on the books and 900+ competing designs in development, unit costs currently range from $1.2 million to over $4 million, and even then operators may only see cost advantages once they scale. Maintenance costs alone for eVTOLs could be up to 50% lower than traditional helicopters, but only if the right infrastructure, certification, and production scale are achieved. Deloitte projects the U.S. AAM market could reach $115 billion USD by 2035, including $57 billion in passenger and $58 billion in cargo operations, with an export potential of $20 billion.

How Isembard’s MasonOS Could Accelerate the eVTOL Industry’s Path to Scale

As the eVTOL sector races toward commercialization, the path to economic viability is becoming clearer, and more challenging. Deloitte’s recent analysis of the Advanced Air Mobility (AAM) market highlights the enormous opportunity: more than 13,000 eVTOL orders, over 900 active aircraft designs, and a projected $115 billion U.S. market by 2035, split nearly evenly between passenger and cargo operations. Yet the same report underscores a core bottleneck: manufacturing scale. With per-unit eVTOL costs still sitting between $1.2 million and over $4 million, and infrastructure and certification hurdles piling up, OEMs must build robust, flexible, and cost-efficient production systems or risk being left behind.

This is where Isembard’s MasonOS offers a compelling advantage, not in avionics or flight management, but in the part of the value chain that Deloitte identifies as most decisive: advanced, scalable, software-driven manufacturing. As discussed earlier, MasonOS is Isembard’s proprietary, AI-native factory operating system that unifies quoting, scheduling, quality control, supply chain coordination, and machine-level programming into a single, intelligence-driven platform. MasonOS can boost factory throughput by 40–60% and reduce operational costs by around 30%, transforming what has historically been a rigid, expensive workflow into a responsive and optimized manufacturing environment.

For eVTOL manufacturers struggling to bridge the gap between prototype and production scale, this is of great significance. Deloitte emphasizes that early cost advantages, like the potential 50% reduction in maintenance costs of eVTOLs relative to helicopters, will only materialize if OEMs can produce aircraft efficiently, reliably, and at scale. Fortunately, MasonOS directly supports this transition by streamlining the processes that typically slow aerospace ramp-up: tooling coordination, digital work instructions, supply chain integration, and the ability to adapt designs rapidly without derailing factory operations.

What makes Isembard’s approach even more disruptive is its franchise manufacturing model. Instead of relying solely on its own facilities, Isembard licenses MasonOS to its franchises, enabling them to operate using the same automation, workflows, and quality systems as Isembard’s flagship sites. This creates a distributed, software-synchronized manufacturing network where capacity can scale geographically, flexibly, and at lower capital cost. For eVTOL OEMs, such a network could help mitigate several challenges Deloitte highlights: supply-chain fragility, regional production needs, and the enormous capital demand required to start up manufacturing from scratch.

This decentralised model also supports governments’ and OEMs’ desire for sovereign manufacturing capability, a recurring theme in aerospace and defense investment. With MasonOS already deployed in Isembard’s first U.S. factory near Dallas, and with additional sites planned through franchise partners, the system offers a blueprint for how to scale precision manufacturing in critical industries without sacrificing the core fundamentals that make it precision manufacturing in the first place: consistency and quality.

In an industry where early orders are often non-binding and certification delays can trigger cancellations, eVTOL companies need every operational advantage they can get. MasonOS doesn’t replace core aerospace engineering, but it strengthens the infrastructure that will ultimately determine which manufacturers survive the transition from concept to commercial reality. By enabling faster iteration, lower costs, and distributed production capacity, Isembard’s software-first model aligns squarely with the pressures Deloitte identifies, and could become a vital catalyst for the eVTOL market’s long-awaited breakthrough into scalable, economically viable manufacturing.

“Like many EV companies, AAM OEMs should secure their supply chains, prioritize optimized manufacturing processes, and carefully monitor the capability to fully scale operations economically (all while maintaining an eye on battery technology).”

Berckman, L., Chavali, A., Hardin, K., Dronamraju, T., Sloane, M., & Kahmann, J. (2023, December 11). Advanced air mobility: Achieving scale for value realization. Deloitte Insights. https://www.deloitte.com/us/en/insights/industry/aerospace-defense/advanced-air-mobility-evtol-aircraft.html

“Continue to invest in suppliers’ capabilities-including digital tools-to align them with production rate increases”.

– 2026 Aerospace and Defense Industry Outlook: Contracting and procurement. Deloitte Research Center for Energy & Industrials.

Deloitte’s recommendation to “continue to invest in suppliers’ capabilities, including digital tools, to align them with production rate increases” directly reflects the approach taken by Isembard and its factory operating system, MasonOS. Isembard’s distributed manufacturing model strengthens supplier capability by enabling rapid, scalable production across highly regulated sectors such as aerospace and defense. Central to this model is MasonOS, an integrated, AI-driven operating system that connects every aspect of factory operations, from quoting and scheduling to machine control, quality assurance, and operator support, into a unified digital workflow. By continually learning from production data and optimizing processes in real time, MasonOS embodies the type of advanced digital tooling Deloitte identifies as critical for meeting accelerating production demands. Together, Isembard and MasonOS illustrate how modern suppliers can use sophisticated digital infrastructure to increase resilience, improve efficiency, and reliably scale output in alignment with industry growth.

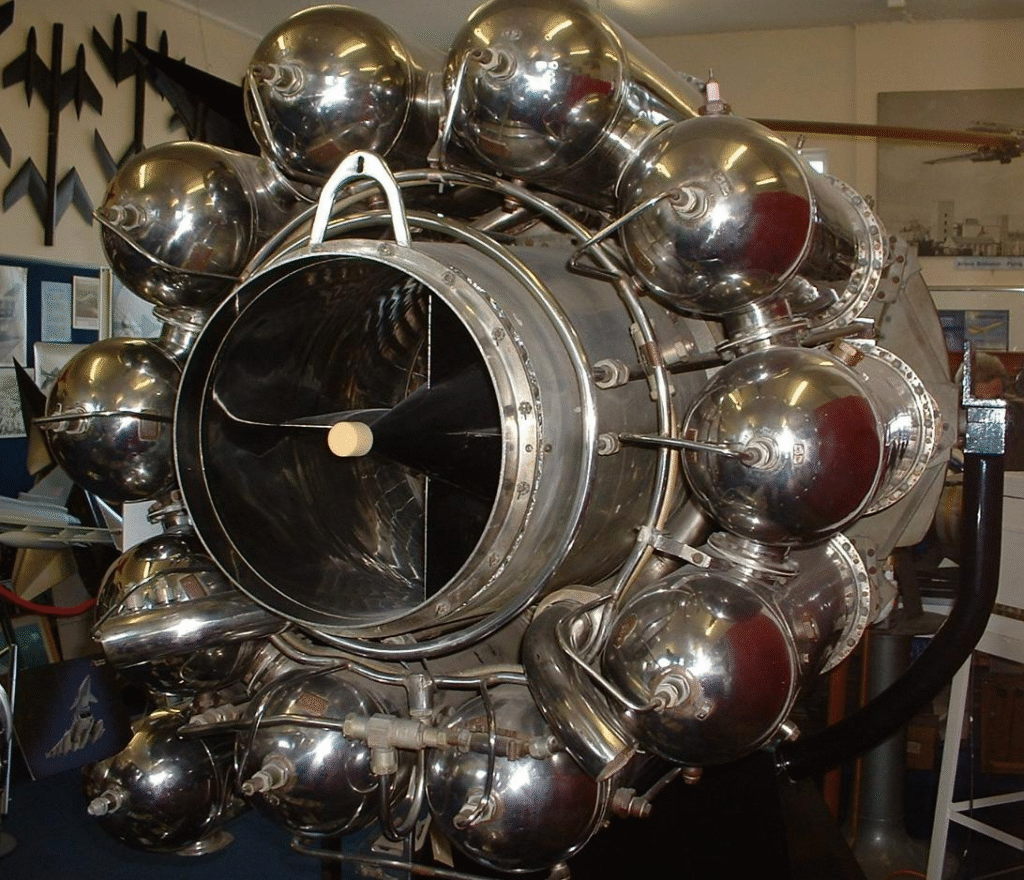

“We haven’t talked about it that much, but on some details of the technical unit and some of the most sort of precision work that we’re doing with some of our most exciting customers are exactly in the propulsion space. Working on really complex parts and all of the key, turbo machinery, let’s say, engines that are going in, for example, very long range drones. This is, you know, work that we’ve been doing at scale for some customers.” – Andrew Kramer, Head of Strategic Deployments at Isembard

A Maverick in the Making: Alexander Fitzgerald’s Path Towards Forging Isembard

Alexander Fitzgerald, the founder and CEO of Isembard, brings a strong entrepreneurial background to the company, having previously built a broadband and telecom business (Cuckoo Broadband). Leveraging both his experience scaling technology-driven ventures and support from investors including Notion Capital, 201 Ventures, and The Forward Fund, Mr. Fitzgerald founded Isembard in 2024 with the goal of modernizing critical-industry manufacturing. Under his leadership, the company is developing software-first, high-precision factories designed to serve sectors such as defense, aerospace, and clean energy, by combining innovative technology with operational expertise to address complex manufacturing challenges.

Cuckoo Broadband

- Founded by Alexander Fitzgerald, Tommy Toner, and Dan McClure

- Broadband disruptor that brought UK customers access to fast internet without exorbitant fees for terminating services after contract expires

- “24-Hour Eggspress Wi-Fi”

- Aims to get new customers online with a portable 4G Wi-Fi “egg” within 24 hours

Notion Capital Managers LLP

- Europe’s leading early-stage business software investor

- Investor in Isembard

“Isembard is tackling one of the hardest, most ambitious challenges today, bringing software-driven transformation to precision manufacturing. Alex and his team have the vision, technical expertise, and relentless execution needed to redefine this space. We’re excited to back them as they build a new industrial powerhouse.” – Jos White, General Partner at Notion Capital

201 Ventures

- Managed by Eric Slesinger

- Former CIA officer

- Mission to advance freedom and autonomy in Europe

- Invests in pre-seed and seed stage enterprises in security/defense and resilience sectors

- Investor in Isembard

The Forward Fund

- Investor in Isembard

Why Isembard Chose Texas for Its U.S. Hub

Isembard’s decision to establish its North American headquarters in Dallas–Fort Worth is directly tied to Texas’s industrial landscape. For a company aiming to build a large, distributed network of smart factories, Texas offers something rarely found in one place: a massive manufacturing economy, diversified industries, and a deeply entrepreneurial culture.

Texas

- 900,000 manufacturing jobs

- $250 billion or 13% annually of state’s GDP

Justin Baucum, General Manager of Isembard’s first American Hub, (located Dallas-Fort Worth area) explained that Texas was chosen as the location for Isembard’s first U.S. factory for several strategic reasons. First, defense and aerospace opportunities are significant in the region, making it ideal for serving early-adopter customers in critical industries. Second, the state offers robust talent programs and a deep pool of skilled workers, particularly in advanced manufacturing and engineering, which supports the need for high-quality, scalable operations. Finally, Texas has a business-friendly climate and a culture of innovation, which aligns with Isembard’s vision of rapidly deploying modular factories. Being in Texas allows Isembard to lead in reshaping U.S. manufacturing while staying close to customers who value speed, flexibility, and local production.

Mr. Baucum explained the similarities between Isembard and another pioneering tech company, his former employer Amazon:

The biggest lessons from Amazon that Mr. Baucum carries into manufacturing at Isembard are:

- Customer centric: Every process, from production scheduling to quality control, needs to be guided by how it impacts the end customer. Faster delivery, better pricing, and superior service aren’t just goals or slogans; they’re real metrics that drive every decision.

- Speed and agility: At Amazon, even small process improvements can have outsized effects on throughput and satisfaction. At Isembard, they apply the same principle by using software to dynamically adjust production schedules, detect defects early, and optimize workflow in real time.

- Continuous improvement via software: Just as Amazon iterates on algorithms and logistics tools to improve operations, Isembard treats MasonOS as a live, evolving system. Updates are ongoing, enabling faster response to issues, improved factory efficiency, and better overall outcomes.

- Scalable processes: Efficiency at scale requires standardization without sacrificing flexibility. At Isembard, they designed modular factories to replicate best practices across multiple sites while still allowing local optimization.

Ultimately, the combination of customer focus, operational speed, and software-driven adaptability is what allows us to deliver better pricing, faster lead times, and superior service in a complex manufacturing environment.

As noted by Mr. Baucum, Isembard tailors its manufacturing capabilities to meet the rigorous demands of defense, aerospace, and clean energy through flexible, modular, and highly automated production systems. For defense, they see interest from companies working on autonomous vehicles and unmanned systems, which requires precision, repeatability, and compliance with strict regulatory standards. In aerospace, they’ve been involved with the fabrication of reusable rocket components and other high-performance parts that require exacting tolerances and quality control. For clean energy, Isembard’s modular factories are equipped to produce components for small nuclear reactors and other advanced energy technologies, combining safety, scalability, and efficiency. Across all sectors, Isembard’s approach leverages software-driven operations to rapidly adapt workflows, maintain consistency, and deliver complex products faster and more reliably than traditional manufacturing models.

Aerospace: A Natural Fit for Precision Manufacturing

Texas is home to one of the largest aerospace clusters in the United States. 16 out of the 19 Fortune 500 Aerospace companies have operations in Texas. Major organizations like NASA and corporations like Lockheed Martin, Bell, Boeing, Raytheon, L3Harris, Northrop Grumman, SpaceX, Collins Aerospace (RTX), LIFT Aircraft, KBR, Firefly Aerospace, Axiom Space, Aegis Aerospace, Venus Aerospace, WilliamsRDM, VectorNav, Qarbon Aerospace, Alpine Advanced Materials and dozens of Tier-2 and Tier-3 suppliers operate across Dallas–Fort Worth, Austin, San Antonio, and Houston. Texas is also home to 15 active military bases, which generated $151 million to the Texas economy in 2023.

Aerospace requires:

- High precision

- Tight tolerances

- Reliable, repeatable processes

- Fast production cycles for prototyping and spares

These are exactly the domains where MasonOS-based factories excel. For franchisees, this means immediate access to a dense base of potential customers.

NASA Facilities in Texas

- Exploration Park:

- Located in Houston, TX

- 240-acre campus at the Johnson Space Center dedicated to commercial and defense space manufacturing and research, with partnerships with universities and companies.

- NASA/FAA North Texas Research Station (NTX)

- Located in Dallas- Fort Worth,TX

- A field laboratory that supports NASA’s aeronautics research with prototype testing and collaborations

- Texas A&M University

- College Station, TX

- Involved in NASA’s research for manufacturing metallic parts in micro-gravity, a technology to be used in future moon and Mars missions

Two Licensed Spaceports in Texas

Houston Spaceport

- Tenants include:

- NASA

- Venus Aerospace

- Manufacturing the Stargazer (Hypersonic passenger spaceplane)

- Ravn Aerospace

- Warfighter training

- RDT&E

- Axiom Space

- Astronaut training facilities

- Mission control

- Testing labs

- High bay

- Axiom Station (space station) module manufacturing

- Collins Aerospace (RTX)

- Spacesuit development

- Spaceflight systems R&D

- Spaceflight Incubator space

- Intuitive Machines

- Lunar Production and Operations Center

- Mission control rooms

- Propulsion test facility

- Manufacturing

- Lunar landers

- Spacecraft

- Texas Southern University (TSU)

- Aerospace training facility

- Aerospace Management facility

- San Jacinto College EDGE Center

- Aerospace training programs and projects

- Northrop Rice

Midland International Air & Space Port

- Tenants include:

- AST SpaceMobile

- Manufacturer of BlueWalker 3 LEO satellite

- FireHawk Aerospace

- Hybrid rocket testing using 3d printed fuel

- Castelion

- Testing rocket systems and propulsion systems

- Space Nation

- Moon Pioneers Mission astronaut training

- AST SpaceMobile

eVTOL related companies

LIFT Aircraft

- Based in Austin, Texas

- Manufacturer of FFA Ultralight single seater eVTOL aircraft

Qarbon Aerospace – Red Oak, TX

- 772,000 ft² of manufacturing space

- large, complex composites fabrication

- partnered with Supernal (Hyundai subsidiary) on an electric vertical take-off and-landing (eVTOL) project

- supplier for Virgin Galactic

- fuselages and wings Delta class spaceships

GracoRoberts

- based in Arlington, Texas

- largest distributor of aerospace specialty chemicals, owns Resin Formulators, a custom epoxy resin manufacturer for eVTOL aircraft

Oil & Gas: Massive Demand for Fast, Durable Machined Parts

Texas’s energy sector still commands some of the heaviest manufacturing demand in the country. Drilling systems, pumps, subsea equipment, valves, and downhole tools all rely on rapid-turn machining and robust metalworking.

Oil and gas companies are famously demanding — parts must be:

- Durable

- Traceable

- Produced quickly

- Consistent across batches

A franchisee running an Isembard-powered factory is well-positioned to meet this demand with predictable output and AI-assisted quality control.

Major Oil & Gas companies in Texas

- ExxonMobil (Houston, TX)

- Chevron (Houston, TX)

- Phillips 66 (Houston, TX)

- Valero Energy (Houston, TX)

- ConocoPhillips (Houston, TX)

- EOG Resources (Houston, TX)

- Occidental Petroleum Corporation (Oxy) (Houston, TX)

- Enterprise Products Partners L.P. (Houston, TX)

- Energy Transfer (Dallas, TX)

- Hilcorp Energy Company (Houston, TX)

- Weatherford International (Houston, TX)

- Kinder Morgan (Houston, TX)

- Schlumberger (Houston, TX)

- Haliburton (Houston, TX)

Automotive in Texas: A Growing Opportunity for Isembard and Its Franchisees

While aerospace and energy dominate the conversation about Texas industry, the state’s rapidly expanding automotive sector is becoming just as influential — and strategically important for Isembard’s U.S. expansion. Over the past decade, Texas has transformed into a major hub for both traditional automotive manufacturing and the new wave of electric and autonomous vehicle production.

A Texas Automotive Boom

Texas now hosts several major automotive employers:

- General Motors Assembly Plant in Arlington, TX

- Assembly plant occupies 250 acres (1,000,000 square meters)

- One of General Motors’ largest assembly plants

- Manufacturers the Chevrolet Tahoe, Suburban, GMC Yukon, and Cadillac Escalade

- Employs 5,641 personnel (2022)

- Tesla’s Gigafactory outside Austin, TX

- One of the world’s largest manufacturing facilities

- Producing the Model Y, Cybertruck, and battery systems

- One of the world’s largest manufacturing facilities

- Peterbilt (Denton, TX)

- 238-acre site

- Over 2,500 employees

- Trucks manufactured:

- On-Highway: Model 579, Model 589

- Vocational: Model 567, Model 520

- Medium Duty: Model 535, Model 536, Model 537, Model 548

- Zero Emission (EV): Model 579EV, Model 567EV, Model 520EV, Model 220EV

- Toyota’s North American headquarters in Plano

- Has significant engineering and production operations

- Assembly plant in San Antonio, TX

- Capacity Trucks in Longview, TX

- Manufacturer of yard trucks, including hydrogen fuel cell and electric versions.

- International Motors (formerly Navistar) in San Antonio, TX

- Manufacture of Class 6, 7, and 8 diesel and electric trucks

- 900,000-square-foot manufacturing facility (began operations in 2022)

- A growing ecosystem of Tier-1 and Tier-2 suppliers supporting everything from EV powertrains to steering systems, castings, and custom machined components.

- Expanding autonomous vehicle development, fueled by robotics startups in Austin, Houston, and DFW.

- Specialty and performance automotive builders scattered across the state.

Shipbuilding and other Maritime

- Canadian-based Davie will build $1B “American Icebreaker Factory” in Galveston, TX

Texas is rapidly emerging as a new powerhouse in American shipbuilding, and nowhere is that transformation more visible than in Galveston, where a planned $1 billion upgrade of the old Gulf Copper & Manufacturing Corporation yard promises to turn it into a state‑of‑the‑art “American Icebreaker Factory.” Under this initiative, the Coast Guard is slated to receive a fleet of new Arctic‑ready icebreakers and cutters, with several being constructed right on the Texas Gulf Coast. Shipbuilding means thousands of skilled jobs for Texans, reinvestment in local infrastructure, and a revival of heavy‑industry manufacturing that had long waned.

What Isembard Plans to Deliver

Isembard is still in the early chapters of its Western story, but its fresh approach signals a profound shift in how modern manufacturing may evolve. By pairing modular, software-orchestrated factories with an operating system built for real-time precision, the company is showing that scale no longer has to depend on massive infrastructure, exorbitant capital, or decades-old processes. If its momentum continues, Isembard could help unlock a new generation of agile, resilient, and locally rooted production, exactly what advanced industries like aerospace, defense, and energy have been searching for. It’s a bold vision, but one that feels increasingly within reach, and a compelling glimpse into what the future of manufacturing in the West might look like when software drives the factory.

With Isembard bucking the trend, it doesn’t matter whether you are in Weatherford or Westminster, West Texas, West Midlands, or Midland Spaceport, an Isembard franchise lets you take the reigns of everything the West has to offer in and become a manufacturing maverick in your own Western story. There’s no doubt we’ll see more of Isembard in the eVTOL arena, as our beloved industry becomes all the more hungry for high quality manufactured components with fast turnarounds.

eVTOL buzz would like to thank the manufacturing mavericks at Isembard, especially Mr. Andrew Kramer, and Mr. Jason Baucum for being gracious enough to hold interviews with us. Stay tuned for the next rodeo!

More Info:

Isembard (official website): click here

NATO Innovation Fund: click here

Written evidence from Isembard (SUK0007) to UK Parliament: click here

Forging Industrial Acceleration: Isembard’s Mission to Reindustrialise the West: click here

Welcome to Isembard, a factory in London’s Zone 3: click here

Meet Cuckoo, the innovative broadband provider disrupting the sector: click here

Giganet acquires Cuckoo in bid to shake up broadband market: click here

How has deindustrialisation affected living standards in the UK?: click here

Forging Industrial Acceleration: Why We Invested in Isembard: click here

“Shaping The AI-Powered Factory of the Future” – Manufacturing Leadership Council: click here

From vision to value: A road map for enterprise transformation in manufacturing with agentic AI: click here

The Building Blocks of Texas’s Future: Industry, Innovation, and Workforce: click here

Bell invests $632M in Fort Worth aviation manufacturing, job creation: click here

Opinion: OEMs Will Play Critical Role In Establishing AAM’s Aftermarket: click here

2025 Aerospace and Defense Industry Outlook(Deloitte): click here

2026 Aerospace and Defense Industry Outlook (Deloitte): click here

2026 Manufacturing Industry Outlook (Deloitte): click here

Lift Aircraft (official website): click here

Embraer Starts Construction Of Fort Worth MRO Center: click here

Texas Targets the Helm: $1B Investment Signals Shipbuilding Comeback: click here

Davie Unveils Plans for $1B “Icebreaker Factory” in Galveston: click here

U.S. Coast Guard receives historic investment to rebuild under President Trump’s One Big Beautiful Bill: click here

Capacity Trucks (official website):click here

Fuzion wireline trucks: click here

Navistar Celebrates Grand Opening of its Benchmark San Antonio Manufacturing Plant: click here

International Motors plant locations: click here

WilliamsRDM (official website): click here

Saronic (official website): click here

Alpine Advanced Materials: click here

Venus Aerospace: click here

A rare look inside the Denton plant that makes more than 150 trucks a day: click here

Peterbilt Celebrates the Production of its 750,000th Truck at the Denton Manufacturing Facility: click here

Texas Governor’s Office: Aerospace Aviation and Defense: click here

Houston Spaceport tenants: click here

RAVN Aerospace: click here

NASA’s Exploration Park Gains Momentum with New Tenant, Project Partners: click here